Jis Tiain Coating Pan Head Screw Second Punch

Second punch is a conventional die for screw heading machine. It is used for producing screw head and groove parts.

We can produced the second punch accroding to the standard, and we can R&D accroding to the drawing, samples and customer’s request.

ANSI American National Standards Institute

JIS Janpanese Industrial Standards

DIN Deutsch Industrial-Normen

ISO International Standardination Organization

BS British Standards

GB ChinaNatiaonalStandard

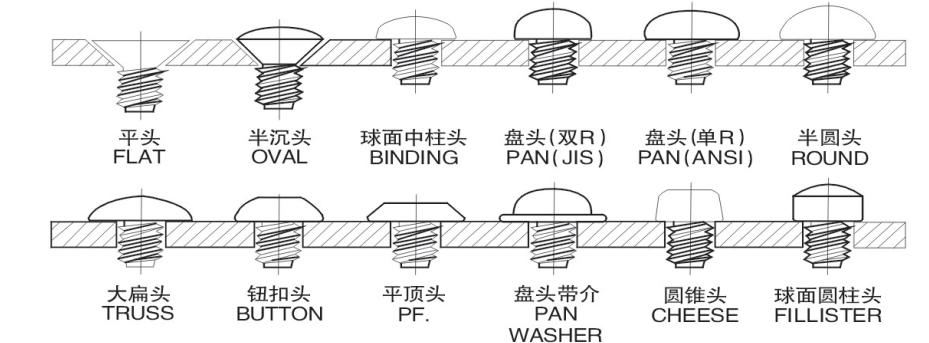

Flat head, Oval head,Binding head,Pan head, Round head,Truss head, Button head, PF head, Cheese head, Fillister head.

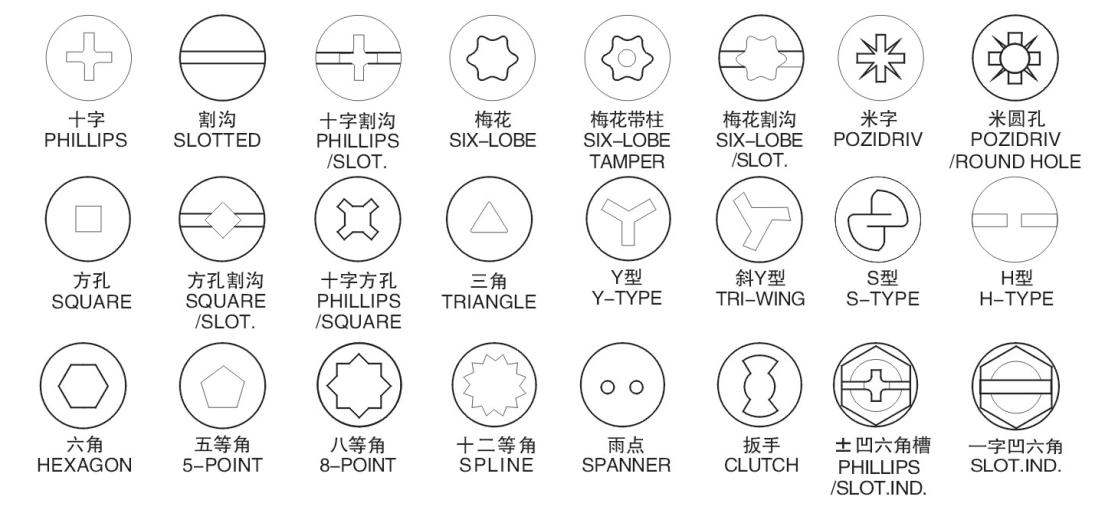

Phillips, Slotted, Phillips/Slot,Six-lobe,Six-lobe tamper,Pozidriv,Pozidriv/Round hole,Square,Square/Slot,Triangle,Y-type,Tri-wing,S-type,H-type,Hexagon,5-point,8-point,Spline,Spanner,Clutch,Phillips/Slot.IND.,Slot.IND.

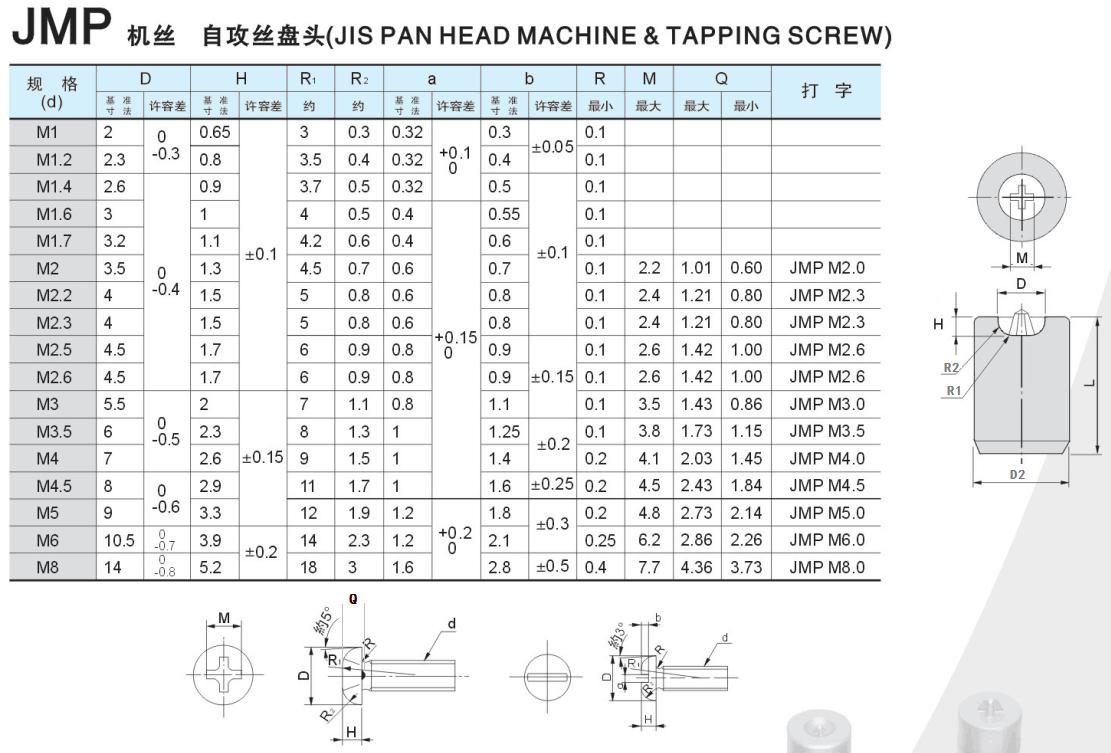

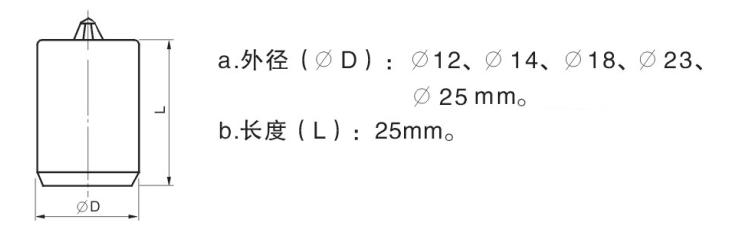

TECHNICAL SPECIFICATION

Diameter: Φ12mm,Φ14mm,Φ18mm,Φ23mm,Φ25mm

Length: 25mm

HSS: M2, M3, M42.

Without coating

TIN coating (Yellow coating)

TiAIN coating (Black coating)

Standard Size:12 Working days

Customization:15-20 Working days

50 Pcs/Size.

Less 50Pcs, should pay mould cost about 40US dollar.

Second punch packed in Green cartons.

We can packed in white cartons by customer’s request.

10Pcs per Box.

Φ12mm 0.24Kgs/Box

Φ14mm 0.32Kgs/Box

Φ18mm 0.55Kgs/Box

Φ23mm 0.85Kgs/Box

Φ25mm 0.94Kgs/Box

Shipment by Air, by Train, by Sea, by TNT, DHL,SF-express.

Thailand,Vietnam,Indonesia,Malaysia,India,Turkey,Iran,Russia,Pakistan,Uzbekistan,Kazakhstan, and more countries or regions.

Choose Chaoyue mould.We effectively reduce the obstacles and the costs for molding in your production and design. Your satisfaction is the eternal pursuit of all Chaoyue staff,we are ready to be your reliable partner and honest friend.

Introduce:

In manufacturing fields where precision and durability are critical, engineers continue to explore innovative technologies to improve product quality. One technology that is receiving a lot of attention is the second punch method of coatings. By combining the potential of coatings like Jis Tiain with the reliability of pan head screws, manufacturers can increase the durability and strength of their products. This blog will explore the significance of the second flush of coatings in improving performance in various industries.

1. Understand the second punching of the coating:

The term “secondary punch” refers to the additional layer of protection provided by a coating on the part or tool. In this case, combining the power of a coating such as Jis Tiain with the use of pan head screws can significantly enhance the functionality of the product. The coating acts as a barrier against corrosion, wear and even temperature changes, ensuring the longevity of the product. Pan head screws, on the other hand, are known for their strength and reliability, providing stability and secure fastening.

2. The function of Yoshida paint:

Jis Tiain is a versatile paint with excellent strength and elasticity. It is known for its resistance to wear, friction and corrosion, making it ideal for a variety of mechanical components. When applied to pan head screws, Jis Tiain coating forms an impermeable layer that extends the life of the screw and improves its overall performance. This unique combination ensures the screws maintain structural integrity even in demanding environments, including heavy machinery or outdoor applications.

3. Strength of pan head screws:

Pan head screws, characterized by a flat cylindrical head with a slightly rounded top and a flat bottom, are widely used due to their reliability and ease of use. By combining these screws with Jis Tiain coating, manufacturers can further enhance the strength of their products. The pan head design allows for a larger contact area, helping to distribute stress evenly across the entire component, ultimately reducing the risk of failure. Coupled with the protection provided by the coating, pan head screws are an excellent choice for applications that require strong fastening.

4. Advantages of coating second punch:

The coating’s over-stamping technology offers numerous advantages to various industries that rely on durable and resilient components. First, the combined strength of Yoshida coating and pan head screws ensures enhanced wear resistance, extending product life. Secondly, the coating protects against corrosion and oxidation, making it an excellent choice for outdoor and marine applications. Additionally, pan head screws increase structural integrity, ensuring components remain tightly secured, preventing potential hazards and reducing maintenance costs.

In conclusion:

This pan head screw second punch has the potential to revolutionize manufacturing. This dynamic combination allows engineers to create rugged products that can withstand harsh environments. By prioritizing durability and strength, manufacturers can ensure their products stand the test of time, benefiting both businesses and end users.